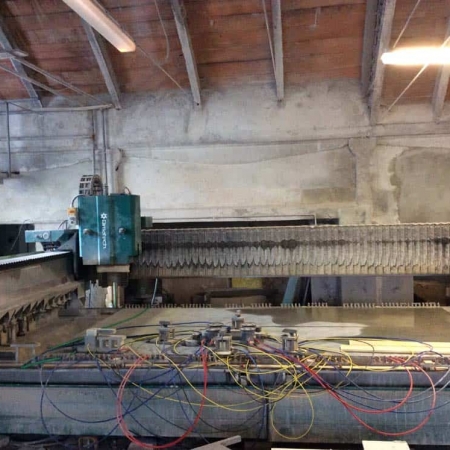

Used CNC Machine Brembana CMS model BOB

- N° 5 interpolated axis

- Axis Stroke “X”: 3.745 mm

- Axis Stroke “Y” : 1.850 mm

- Axis Stroke “Z”: 250 mm

- “C” Axis rotation from 0° to +600°

- “A” Axis inclination from 0° to 90°

- Working thickness from 2 mm to 110 mm

- Useful work dimensions: 2.835 x 1.800 mm

- Tool holders: ISO40

- Tool holders automatic with 22 positions (11+11)

This CNC machine will be reconditioned in our workshop!

Questions from clients:

1. As I see now it is still untouched. When do plan to recondition it?

yes it’s untouched we will start in the next 15 days and if we get a potential seller we accelerate it.

2. As I see X axis stroke would be good for us, however useful work dimensions are only 2835×1800. Why is there such a difference? It would be good to use all available stroke, or at least 3500 in our case as countertops are getting longer and longer and we need to use all available slab length all the time now.

The difference is due to the automatic tool changer magazines. The axis arrives in position to load and unload the tool but the working size is shorter.

NOTE: we will increase the Z-axis stroke, we don’t know how much at the moment but it will be not less than 40cm

3. Is training and starting the CNC at our place included in the price? If not how much will it cost?

If we make the training in our workshop in Italy it’s free for 5 days, if we have to come to your site the price is 300€/per day plus air flight tickets, board and room.

4. Tools. Are any tools available with this CNC center?

Just a few tool holders we found in it. For the tool holders, diamond tools and suction cups we have special prices because we resell them in our e-shop www.amastone.com. They depend on the material you work and on the job you want to make it.

5. Could you provide a brief overview of what operations will it be able to do after recondition is done?

Operation? everything it’s possible to make with Alphacam software or other professionals CAD/CAM systems for the stone industry.

Cutting, shaping, engraving, kitchen-tops, shower trays, vanity tops, shower trays and claddings for the building industry in marble, granite and artificial stone.

6. I need this info for the management to present so we could make a decision whether we will proceed with it.

I understand it of course. I know it’s difficult to choose a machine that at the moment you cannot see reconditioned, but think about it as a new machine, sandblasted, repainted, new software, new computer, new controller and cascaded these all the parts we have to replace. It takes time, around 90 days.

Visit amastone.com, the stone industry marketplace with lots of products from the best brands at affordable prices!